I’ve been geeking out over EV batteries since the early days of the Leaf, always chasing that next leap in range and efficiency. So when Stellantis dropped news of their IBIS battery in September 2025, tested in a Peugeot e-3008, it stopped me in my tracks. This Intelligent Battery Integrated System skips the separate charger and inverter, squeezing 10% more range from the same pack size and shaving 40 kg (88 pounds) of weight. As a car nut who’s driven EVs from coast to coast and felt the pinch of conversion losses, this feels like a smart hack that’s simple yet game-changing. Let’s unpack how IBIS works, the test results, and what it means for Stellantis brands like Jeep and Chrysler.

How IBIS Works: Software Smarts Over Hardware Bulk

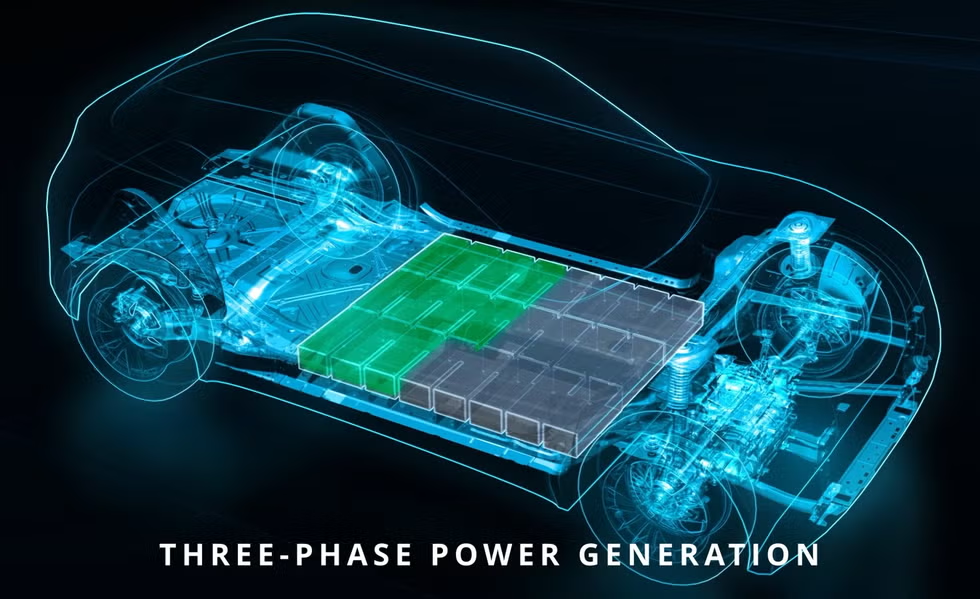

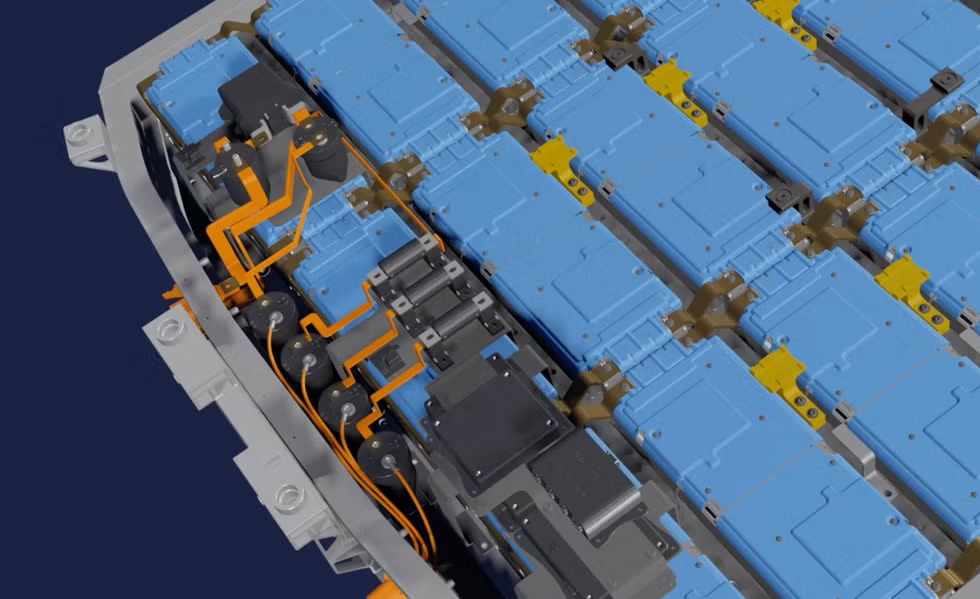

The IBIS battery is all about ditching the bulky charger and inverter that hog space in most EVs. In a typical setup, the charger converts AC from the wall to DC for the battery, and the inverter flips DC back to AC for the motor. IBIS does both with software controlling each of the 24 modules individually—288 NMC cells in a 65 kWh pack. By arranging modules in three groups of eight in series and switching lines, it outputs three-phase AC for the motor and converts incoming AC to DC for charging. No extra hardware means less weight and no energy loss from conversions, plus a cubic foot of freed space that could trim drag. Stellantis VP of Research Anne Laliron called it a “10 percent gain” in efficiency, tested in a standard e-3008 on the WLTC cycle—lower consumption and 10% faster AC charging (six hours vs seven on a 7 kW station). The 170 kW (228 hp) output is 15% higher than a standard inverter, and it’s scalable for AWD or cell-to-pack designs.

Real-World Testing: From Stationary to Road-Ready

IBIS started as a stationary grid battery, running three years strong, but EVs demand more—peaks and troughs that stress packs. Stellantis, partnering with Saft, E2CAD, and Sherpa Engineering (backed by France’s Future Investment Plan), tested it in the e-3008, a STLA Medium platform SUV for future Jeep, Chrysler, and Dodge models. The results? 10% less energy use on the road and during charging, all while keeping the pack the same size. That means a 275-mile EV could hit 300 miles, or smaller packs match current range at lower cost. The software compensates for module variations, even allowing different chemistries in the same pack—like GM’s Ultium idea. It’s not exotic; the circuitry uses off-the-shelf parts, making it cost-effective.

The Bigger Picture: Solid-State on the Horizon, But IBIS Wins Now

While solid-state batteries promise the holy grail—Mercedes’ EQS prototype did 750 miles in September 2025—IBIS is here sooner, potentially by 2030. Panasonic’s anode-free lithium-ion, which forms the anode after first charge, could boost capacity 25% (e.g., Model Y from 337 to 421 miles), but IBIS is Stellantis’ play for immediate gains. It’s part of a broader EV push, with STLA Medium underpinning affordable models. For me, as an EV driver who’s felt the drag of extra weight, this is the kind of innovation that makes sense—simple, effective, and ready to roll.

IBIS Could Be the Quiet Revolution EVs Need

Stellantis’ IBIS battery is the kind of under-the-radar breakthrough that could make EVs lighter, cheaper, and longer-ranging without waiting for solid-state magic. The 10% efficiency jump in the e-3008 test is real, and the weight savings are a win for handling and range. If it hits production by 2030, it could give Jeep and Chrysler an edge. As someone who’s lugged around extra charger hardware in my EV, I’m all for it. What do you think—IBIS a sleeper hit or just another tweak? Share below; I’d love to hear from fellow EV folks!

Source- caranddriver