New batteries and ultra-compact e-axles from Rimac aim to boost energy density,

cut weight, and reshape the next generation of hypercars and EVs.

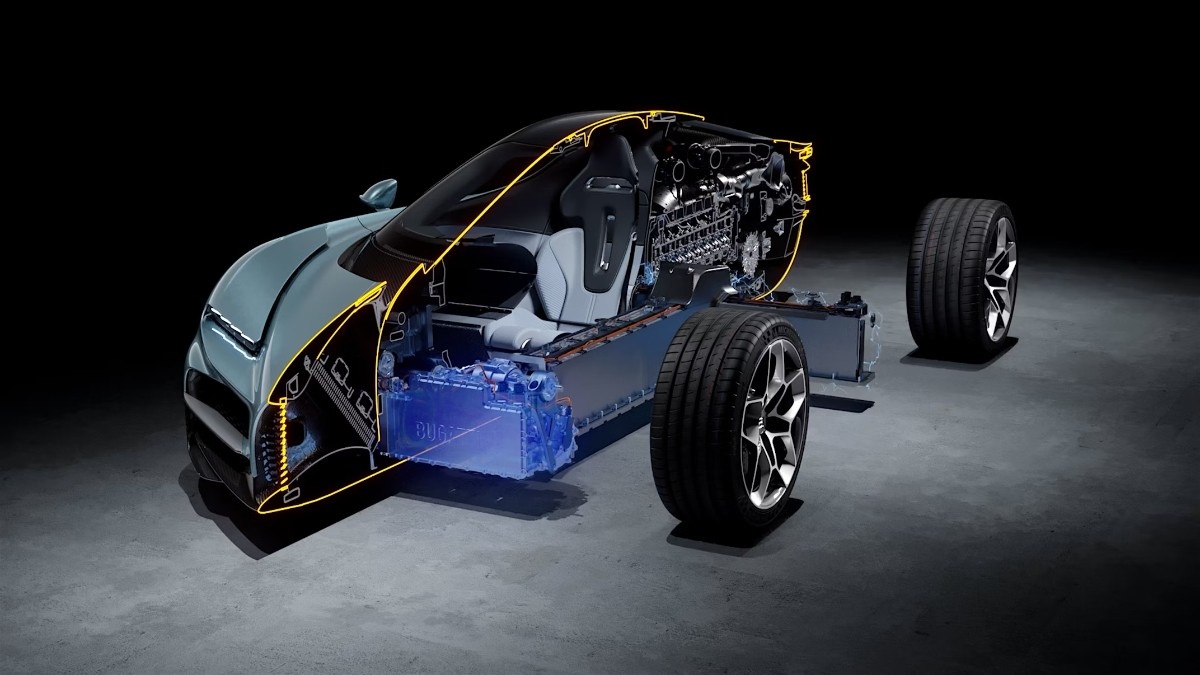

Bugatti’s future is starting to come into focus, and it looks less like a fuel-gulping W-16 and more like a finely balanced blend of combustion and cutting‑edge electrification. As the brand transitions away from its legendary quad‑turbo sixteen‑cylinder era, partner company Rimac Technology is preparing a suite of solid‑state batteries and high‑output e‑axles that could underpin Bugatti’s next halo model early in the next decade.

Solid-state batteries for the next Bugatti

The latest glimpse behind the curtain comes from Rimac Technology chief operating officer Nurdin Pitarevic, who recently discussed the company’s battery and motor roadmap in an interview with European media. He outlined a solid‑state battery program being developed with Taiwanese cell specialist ProLogium and composite materials teams at Mitsubishi, with a clear target: a new Bugatti model due around 2030.

According to Pitarevic, development is already in an advanced phase, with prototype packs moving toward vehicle‑level testing. The company is positioning these batteries for what he calls “mid‑volume” production in the Bugatti context—still tiny by mass‑market standards, but notable for a brand that builds cars in the hundreds rather than tens of thousands.

How the new batteries differ

Rimac’s solid‑state pack is being designed to deliver a step change in both energy density and mass. In prototype form, a 100‑kWh pack is said to be roughly 20–30 percent more energy dense than current nickel‑manganese‑cobalt (NMC) lithium‑ion batteries of similar capacity, while trimming about 30 kilograms (around 66 pounds) from the system weight. Much of that saving comes from a new ultra‑stiff composite housing, developed with Mitsubishi, which allows the pack to act as a structural element while using less material.

From a technical standpoint, the move to a solid electrolyte instead of conventional liquid or gel electrolytes opens the door to higher operating voltages, improved thermal stability, and faster charging capability. Pitarevic has indicated that these packs are being engineered to support significantly higher charge rates than today’s packs, with safety margins that make repeated fast charging more acceptable in high‑performance use.

Compared with existing high‑end NMC systems used in hypercars, the Rimac solid‑state approach aims to deliver more energy in the same or smaller packaging volume, with lower weight and improved abuse tolerance. For a brand like Bugatti, which has historically balanced enormous power with substantial curb weights, every kilogram matters for braking, cornering, and repeatable performance.

Compact e‑axles: power, packaged smarter

The batteries are only half the story. Rimac Technology is also developing a new family of integrated e‑axles—units that combine electric motor, gearbox, and power electronics in a single assembly. Pitarevic describes a modular system capable of outputs between roughly 200 and 470 horsepower per axle, adaptable to front‑, rear‑, or all‑wheel‑drive configurations and suitable for both full EVs and plug‑in hybrids.

One example under development for an SUV from Saudi‑backed EV startup CEER reportedly weighs about 132 kilograms (291 pounds) while offering power comparable to one of the 612‑hp, 198‑kg (436‑lb) rear motors used in the Rimac Nevera. Another e‑axle variant is targeting around 500 horsepower from a unit weighing just 48 kilograms (106 pounds). For vehicle engineers, these numbers are significant: more power and torque in a tighter, lighter package means more freedom in chassis design, weight distribution, and aero packaging.

Compared with many current production e‑drives, which can be bulky and heavily overbuilt, Rimac’s next‑generation units are clearly skewed toward power density—horsepower per kilogram and kilowatt per liter—rather than low cost. That makes them particularly suited to low‑volume performance applications such as Bugatti, but also attractive to premium brands like BMW and Porsche, both of which have been named as early customers alongside CEER.

Why this matters for performance cars

For the next Bugatti, combining a lighter, more energy‑dense pack with ultra‑compact e‑axles opens several doors. Engineers can place the battery lower and more centrally in the chassis while trimming overall weight, improving both center of gravity and yaw inertia. Smaller, lighter drive units at each axle give more flexibility in fine‑tuning torque vectoring and traction control, which is critical when power figures push well beyond 1,000 horsepower.

In practice, that means a future Bugatti could deliver similar or greater straight‑line performance than today’s hypercars, while improving repeatability on circuit runs, brake performance, and overall agility. Better thermal behavior and higher permissible charge rates also matter for owners who drive hard at track events and then want to recharge quickly without stressing the battery.

There’s a downstream effect too. Once the technology is proven in ultra‑low‑volume vehicles, the same solid‑state chemistry and power‑dense e‑axles can be adapted—perhaps in detuned form—for fast GTs, high‑performance SUVs, or sportier variants of mainstream EVs from partner brands. Achieving cost parity with current NMC packs around the mid‑2030s, as Pitarevic suggests, would be a key milestone for that wider rollout.

Comparison with today’s systems

Most current high‑performance EVs still rely on advanced lithium‑ion cells with liquid electrolytes, coupled to large, separate inverters and relatively heavy motor housings. Even at the top end—cars like the Nevera, Taycan Turbo GT, or Model S Plaid—engineers often face trade‑offs between pack capacity, peak power, and weight.

Solid‑state technology, if Rimac meets its targets, would shift that balance. A pack that is 20–30 percent more energy dense could either increase range for a given footprint or allow a smaller, lighter pack with similar usable energy. When combined with e‑axles that deliver similar power to current systems at drastically reduced mass, the net effect is a meaningful improvement in vehicle power‑to‑weight ratio and efficiency.

For hybrid supercars, where combustion engines and electric components must share limited space, packaging gains may be even more important than raw power. Smaller e‑axles free up room for larger engines, more sophisticated suspension layouts, or improved cooling systems—all critical to maintaining consistent performance under track conditions.

Implications for the wider EV market

Rimac has made it clear that its production volumes will remain relatively low, aligned with its focus on high‑end applications rather than mainstream EVs. However, Pitarevic has indicated that the company is open to licensing its solid‑state technology once it is fully validated, and the early customer list for the new e‑axles—BMW, Porsche, and CEER—shows that major OEMs are paying close attention.

If cost parity with current NMC cells is achieved around 2035, solid‑state packs could begin to appear in performance‑oriented trims of more accessible vehicles, especially where range and weight are critical selling points. Meanwhile, the e‑axles’ modularity makes them strong candidates for premium EV platforms that need both flexibility and high output without excessive mass.

Looking ahead

Taken together, Rimac’s solid‑state battery program and compact e‑axles sketch a credible path for Bugatti’s post‑Tourbillon era: lighter, more efficient electrified hypercars that still deliver the brand’s trademark performance, but with far more sophisticated energy management and packaging. The timelines remain long—first applications around 2030, broader cost competitiveness by the middle of the next decade—and much depends on real‑world durability and manufacturability.

Even so, the direction is clear. As combustion engines retreat from the center of the hypercar stage, energy‑dense batteries and power‑dense electric drive units will become the new differentiators. If Rimac can deliver what its engineers are promising, the next Bugatti—and the high‑end EVs that follow it—may mark a significant step forward in how performance is engineered, not just measured on a spec sheet.