Ford’s attempt in the 1980s to build an internal combustion engine without any oil—yeah, you read that right. Instead of the usual slop of lubricants, they dreamed up a system with a gas cushion and fancy ceramics to keep everything humming. It was supposed to be a game-changer for fuel efficiency and easy upkeep, but it never saw the light of day. Having spent my share of afternoons covered in grease from oil changes on my beat-up pickup, I’ve always wondered what went wrong with this clever setup. Let’s chat about the tech, the snags, and why it still echoes in today’s rides.

The Clever Trick That Powered It All

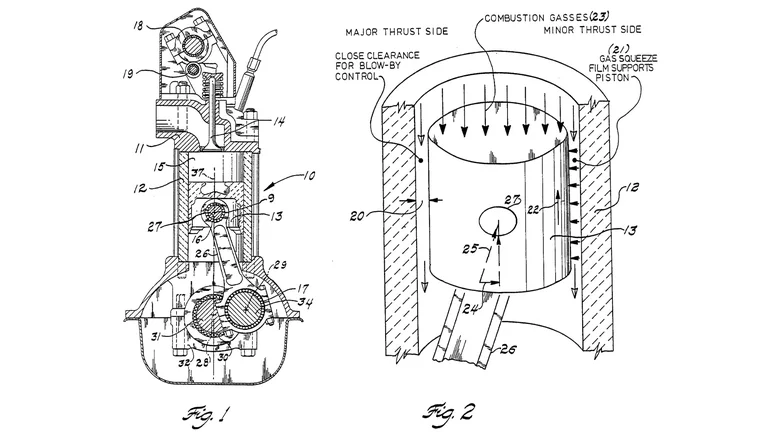

During those gas-crunch years of the ’80s, Ford’s team got inventive. They came up with a “gas squeeze film” where the piston’s up-and-down action pulled air into tiny grooves, creating a buffer that kept parts from rubbing. No oil meant no drag, and to deal with the intense heat—think 1,600°C (2,912°F)—they used ceramics like silicon nitride and zirconia, stuff that’s tough as nails and doesn’t sweat the high temps. Without piston rings and with gaps thinner than a hair at 0.001 inches (0.025 mm), it aimed for blow-by under 2% once revs hit 1,500 rpm. Cleaner burns, less waste—it sounded like the engine I’d love to drop into my old truck for hassle-free weekends.

What Made It So Exciting Back Then

This wasn’t some half-baked idea; it could’ve flipped the script on cars. Cutting friction promised better mileage, a big deal when pumps were pricey. Ceramics let it run hot, squeezing more power from every drop of fuel while trimming emissions. And ditching the oil system? That meant lighter weight and fewer trips under the hood—music to my ears after too many sticky oil filters. The prototypes ran smooth in tests, teasing a world where engines were as low-fuss as riding a bike. For a young me poring over those mags, it felt like tomorrow’s tech was just a tweak away.

The Messy Problems That Sunk It

But dreams crash hard sometimes. Keeping those super-tight gaps steady amid heat swells, shakes, and road grit was like balancing on a tightrope in a windstorm—any speck of dust could scratch the ceramics and spell disaster. Shaping those materials was a wallet-drainer, precise as watchmaking but on a bigger scale. And get this: even if the pistons went oil-free, the rest of the engine still craved cooling and cleaning, so oil hung around anyway. Scaling it for factory lines? No dice—the price tag was too steep, and it was picky about conditions. By the end of the decade, with hybrids peeking over the horizon, Ford tucked it away. Still, its bits inspired today’s slick coatings in engines.

Others Gave It a Shot Too

Ford had company in this chase. Toyota and Nissan poked at ceramic setups around the same time, hunting for that friction-free edge, but they tripped over the same hurdles: too expensive, too brittle, too tricky for everyday use. Everything stayed in the prototype phase—no road cars ever got the treatment. Jump to now, and you see hints of it in hybrid wizardry, like the Renault Clio’s efficient mill, or tough materials in EVs such as the Tesla Model S. It’s not a straight copy, but those ’80s tinkerers nudged things forward.

Wrapping It Up: A Revival or Just a Story?

As I fiddle with my truck’s engine on lazy Sundays, I grin thinking about Ford’s gutsy swing. An oil-free beast in 2025 seems unlikely—EVs are stealing the show, and solid-state batteries are the hot topic—but maybe ceramics sneak back in for hybrids or racers. Ford’s miss wasn’t a flop; it sparked smarter designs we use now. What’s your spin—could oil-free engines roar back, or are they a fun tale for us car lovers? Chime in below; I’m curious what you folks think.